1)One button operation

2)Competitive price for distibutor

3)Reliable support and easy maintenance

4)Heavy duty

PET flake plastic color separating machine

PET flake plastic color separating machine is widely used for recycled plastic flake or granule producer to separate plastic flake or granule and remove impurity throught color difference. Plastic color sorting machine is designed for recycled plastic manufacturer with high production capacity. Color sorter machine can separate different color plastic flake and gruanule for it is installed colorful CCD camera with high definition and accuracy.

PE plastic flake color separation result:

Raw PE flake Red PP Green and blue PP

PE plastic color sorting machine Specification

|

Model |

RC3-64X |

RC4-64X |

RC5-64X |

RC6-64X |

RC7-64X |

RC10-64X |

|

Throughput(T/H) |

1.5-9 |

2-12 |

2.5-15 |

3-18 |

3.5-21 |

5-30 |

|

Accuracy(%) |

≥99.9 |

≥99.9 |

≥99.9 |

≥99.9 |

≥99.9 |

≥99.9 |

|

Optimal Reject Rate |

≥10:1 |

≥10:1 |

≥10:1 |

≥10:1 |

≥10:1 |

≥10:1 |

|

Weight(KG) |

800 |

1000 |

1100 |

1350 |

1450 |

1750 |

|

Power(KW) |

0.6-0.9 |

0.7-1.0 |

0.8-1.1 |

1.1-1.4 |

1.2-1.9 |

1.4-2.3 |

|

Dimension |

1510*1876*1850 |

1510*2192*1850 |

1510*2558*1850 |

1510*2905*1850 |

1510*3245*1850 |

1500*4320*1850 |

|

Air Pressure(MPa) |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

0.6-0.8 |

|

Air Consumption(m³/min) |

1.8 |

2.4 |

3.0 |

4.0 |

5.5 |

9.0 |

|

Voltage |

220V/50Hz |

220V/50Hz |

220V/50Hz |

220V/50Hz |

220V/50Hz |

220V/50Hz |

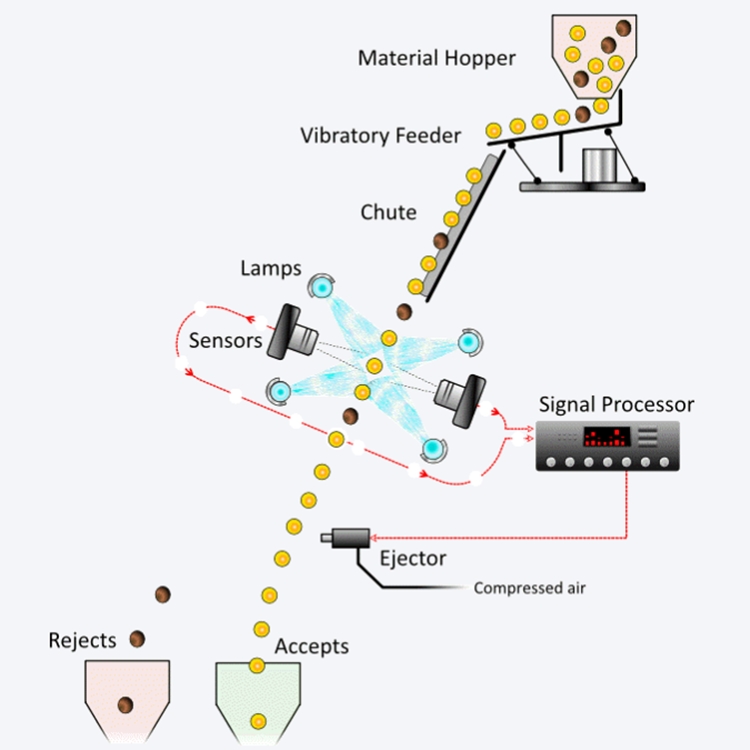

Working principle of plastic color separator:

Plastic color sorter can separate plastic flake or granule by slightly color difference, plastic color sorter can also remove small stone, impurity of plastic, recently shape sorting is also used for plastic classification.

High speed CCD camera scans objects that fall from vibrating chutes, ejectors will blow away the material with different color through compressed air, optimized algorithm is the core technology of color sorter, our machine can also reject material by only the photo, it is so efficient for changeover.

Core advantage

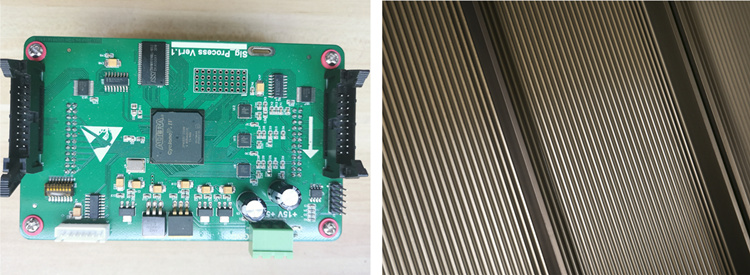

1. 10K Nikon CCD camera with high definition, sorting accuracy up to 0.01mm², customized lens to achieve clear image without distortion

2. USA chip, ARM+ FPGA, powerful hardware with intelligent algorithm.

3. Durable LED system satisfy requirements of different color identification,separation and classification.

4. Synchronization system makes the adjustment work into ONE BUTTON OPERATION, rejection by photo is available.

5. Ejectors longer has longer lifetime, lower air consumption, faster speed, easier maintenance and high sorting accuracy.

6. Wider chute up to 332mm makes increase production capacity.

7. Self-checking system makes the machine can check the ejectors, cameras, control boards and background boards automatically.

8. No wearing parts(except mine stone color sorter) makes 0 maintenance cost.

Nikon colorful CCD camera Heavy duty rejector with long lifetime

ARK filter Touch screen with synchronization system for easy adjust

MeanWell power supply

USA chip 332MM wide chute

Stable vibrator

Field of application for plastic color separation machine

After-sale Service

• 24/7 online support

• We can provide 3-7 days testing & training in customer's site without charge

(please bear engineer's air tickets fees, and arrange accommodation)

• Within warranty, factory provides free spare parts, user bears freight

• After warranty, labor cost of engineer is 100usd per day, please also bear fees of all round air ticket and accommodation

Package & Shipment